WOODWORKING

Project Guide

Level 3

November

2004

“Learn To Do By Doing”

TABLE OF CONTENTS

Level Three Objectives ..................................................................................................................................1

Achievement Day Requirements

..................................................................................................................3

Additional Resources ....................................................................................................................................5

Safety in the Woodworking Project

..............................................................................................................7

Safety Contract (to be signed)

.......................................................................................................................9

Forestry Industry .........................................................................................................................................11

Drafting, Drawing & Dimensioning

..............................................................................................................13

Joinery .........................................................................................................................................................15

Power Tools .................................................................................................................................................19

Clamping & Gluing

.......................................................................................................................................25

Additional Hand Tools .................................................................................................................................29

Sharpening of Tools ....................................................................................................................................31

Woodworking Tips ......................................................................................................................................33

Things to Make ............................................................................................................................................35

Members: I Can Checklist

...........................................................................................................................57

Evaluation ....................................................................................................................................................61

1

ALB E RTA 4-H W OOD W ORKI N G PR O JECT LEV E L TH REE

LEVEL THREE OBJECTIVES

Members will be able to:

1. Work safely with wood to produce personal projects made of wood.

2. Identify and use woodworking tools and supplies in a safe manner.

3. Challenge themselves with a variety of projects and varying levels of complexity of tasks in woodworking.

4. Work cooperatively with others in a workshop environment.

5. Develop skill in decision making, leadership, problem-solving, finances and communication.

2

ALB E RTA 4-H W OOD W ORKI N G PR O JECT LEV E L TH REE

3

ALB E RTA 4-H W OOD W ORKI N G PR O JECT LEV E L TH REE

ACHIEVEMENT REQUIREMENTS

Level Three:

1. Completed Record Book

2. At least two completed projects which use different types of joints and which required the use

of power tools studied in this project.

3.

Plans drawn by the member for a personal project. Cardboard model of intended project.

4. Item made by the member which required the use of a router.

5. Display of tools sharpened by the member. (Chisels, screwdrivers etc.)

4

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

5

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

ADDITIONAL RESOURCES

People

• local woodworkers

• teachers

• family members

• other 4-H members or leaders

Places, Events and Organizations

• local woodworking clubs

• exhibitions and fairs that have a woodworking class

• colleges that offer woodworking, design, or similar courses

• displays

• museums sometimes have displays with wooden articles

Things

• books or magazines

• C

anadian Home Workshop

• W

ordworkers Journal

• W

ood Magazine

• A

merican Woodworker

• furniture

• buildings featuring wood

Web sites

www.thewoodcrafter.net

www.leevalleytools.com

www.woodworkershop.com

www.intheworkshop.com

www.uniqueprojects.com

www.am-wood.com (Amateur Woodworker)

www.northpolechristmas.com

www.tdc.ca/ewebster.htm

www.feesa.ab.ca

www.woodlinks.com

6

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

7

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

SAFETY IN THE WOODWORKING PROJECT

List as many preventative actions as you can for the following risks:

AT RISK RISK PREVENTATIVE ACTION

EYES

Flying chips

Dust

Splashing finishes

Splinters from breaking tools

Fumes

Compressed air used improperly

EARS

Exposure to loud noises

LUNGS

Exposure to very tiny dust particles

(less than 10 microns)

Exposure to fumes from finishes

Inadequate ventilation

SKIN, FINGERS, LIMBS,

HANDS AND FEET

Punctures, rips from tools and rough wood.

Crushing

Pinching

Exposure to chemical finishes

Abrasions

Burns from hot tools

BACK

Lifting too much

Falls from tripping over materials

Turning incorrectly

Lifting incorrectly

You must purchase your own personal safety equipment for the 4-H woodworking project.

Eye protection must be worn.

8

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Who does an unsafe worker affect?

Safety Steps

1. Name the risks

2. Safeguard the work area.

3. Wear necessary protective equipment.

4. Use the right tools.

5. Follow correct procedure.

6. Monitor work habits.

7. Correct as necessary.

Ensure all helpers follow safe procedures

• Where are the First Aid kits kept at your 4-H meetings?

• Where are all the First Aid kits at home?

• Who has First Aid training in your 4-H club?

• Who has First Aid training in your family?

• What phone number do you call for emergency help?

• What are the directions to drive to your meeting place? (In case you ever had to give them to

emergency people)

•

What are the directions to get to your home? (In case you ever had to call emergency people)

Post these by all the phones in your home or shop.

Contents for a Basic First Aid Kit

A variety of bandages; antiseptic; tweezers; First Aid booklet; cotton swabs; sterile gauze; First Aid tape;

needles (to get out slivers); eye drops.

9

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

SAFETY CONTRACT

I Will:

identify risks of activities

take actions to eliminate or reduce risk

ask for help when needed

select the correct tools, equipment and materials for activity

watch for and allow for closeness to other people

stop work and move back when ask to

exit work area on command (in case of emergency)

return tools and supplies to storage after use

follow safe disposal procedure

dress appropriately for club activities

share responsibility for safety in the club

Member

Parent

Leader

Date

10

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

11

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

FORESTRY INDUSTRY

Objectives

Members will be able to:

• identify forestry as one of Alberta’s major industries and employers

• trace the route of wood products from wood lot to consumer

• name at least five careers linked to forestry and the preparation for that career

• list sources of information on the forestry industry

Facts On Forestry

• Canada is the world’s largest exporter of wood and wood products

• forest products were one of the largest contributors to the surplus balance of trade

for Canada in 2001

•

Canada has 10% of the world’s forests

• 60% of Alberta is covered by forest

• The forestry sector provides approximately 54,000 jobs in Alberta

• The forestry sector generates $1.6 billion in household income in Alberta

• The forestry sector is the primary industry in at least 45 communities in Alberta

Forestry Related Career Opportunities

• Research and development

• Logging

• Trucking and other services

• Manufacturing of forestry products

• Environmental protection

• Fire protection

Training and Education Opportunities re: Forestry

• University of Alberta – Faculty of Agriculture and Forestry

• Junior Forest Rangers Program – Alberta Sustainable Resource Development

• NAFA (National Aboriginal Forestry Association)

• Alberta Forestry Advanced Management Institute (Hinton)

• Silviculture Institute of British Columbia

• Lakehead University, Thunder Bay

Visit www.woodlinks.com for additional information on forestry careers.

12

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

13

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

DRAFTING, DRAWING & DIMENSIONING

Isometric Drawings

• Shows what an object would look like from one side and a bit below your eyes (like looking

down at something sitting on a table)

•

Is helpful for getting an idea of what the project will look like

• Helps indicate what type of materials will be needed

Sketch an example of an isometric drawing here.

Orthographic Drawing

• This type of drawing splits the object into different views: the top, the sides and the front

• An orthographic drawing is drawn accurately and to scale*

* to scale means that each measurement on paper is in proportion to a measurement in real life. e.g. One cm

on paper represents 10 cm in real life.

Sketch an example of an orthographic drawing here.

14

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Sources of Plans, Patterns

Web sites

www.thewoodcrafter.net

www.leevalleytools.com

www.woodworkershop.com

www.intheworkshop.com

Books

Check out the library!

Your Imagination

And, best of all your own head!

Someday you will need a special item for a particular spot. You may look in stores or catalogues to see if the

right thing is out there for sale. Then it hits you! I can make this myself! Here’s how to do it.

Custom Designs by Me

1. Decide what you want this project to do for you. What are the requirements of the project?

Let’s say you want to build a shelf for your school locker. There will be size limitations. It will

have to be a certain strength. Do you want it to be adjustable, so you can move it up and

down? Will you have to assemble it after you have put the pieces in the locker or can you

preassemble it at home? Do you plan to store heavy or light objects on this shelf?

2.

Take measurements of the space to be occupied by the project. Measure your locker door.

Measure the inside of the locker.

3.

Make both isometric and orthographic drawings of the project. This step helps you think

through the building and use of the item.

4.

Make a paper or cardboard model of the project. Test it in the space that you intend to use the

actual article. Many design problems are detected at this stage! It is a lot cheaper to discover a

mistake with a paper model than it is with an expensive wood object!

5.

Make any necessary design changes. Repeat your test.

6. Transfer your pattern to wood. Proceed with building the real article.

7. Install, use and appreciate your custom designed project.

8. Take a picture for your record book!

15

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

JOINERY

Dovetail

A variety of joints have been designed and used by woodworkers. They vary in procedure, strength,

appearance and skill required to make them. Some of the techniques used by pioneers with crude tools are

still holding today!

When buying wooden furniture, the quality of joints used indicates the strength and quality of the furniture.

The better quality the joints, the more expensive the furniture. You will make at least two different types of

joints for this project.

Different joints are suitable for different purposes. Choose the correct joint for your project. Then, construct

it properly. Glue and clamp it securely.

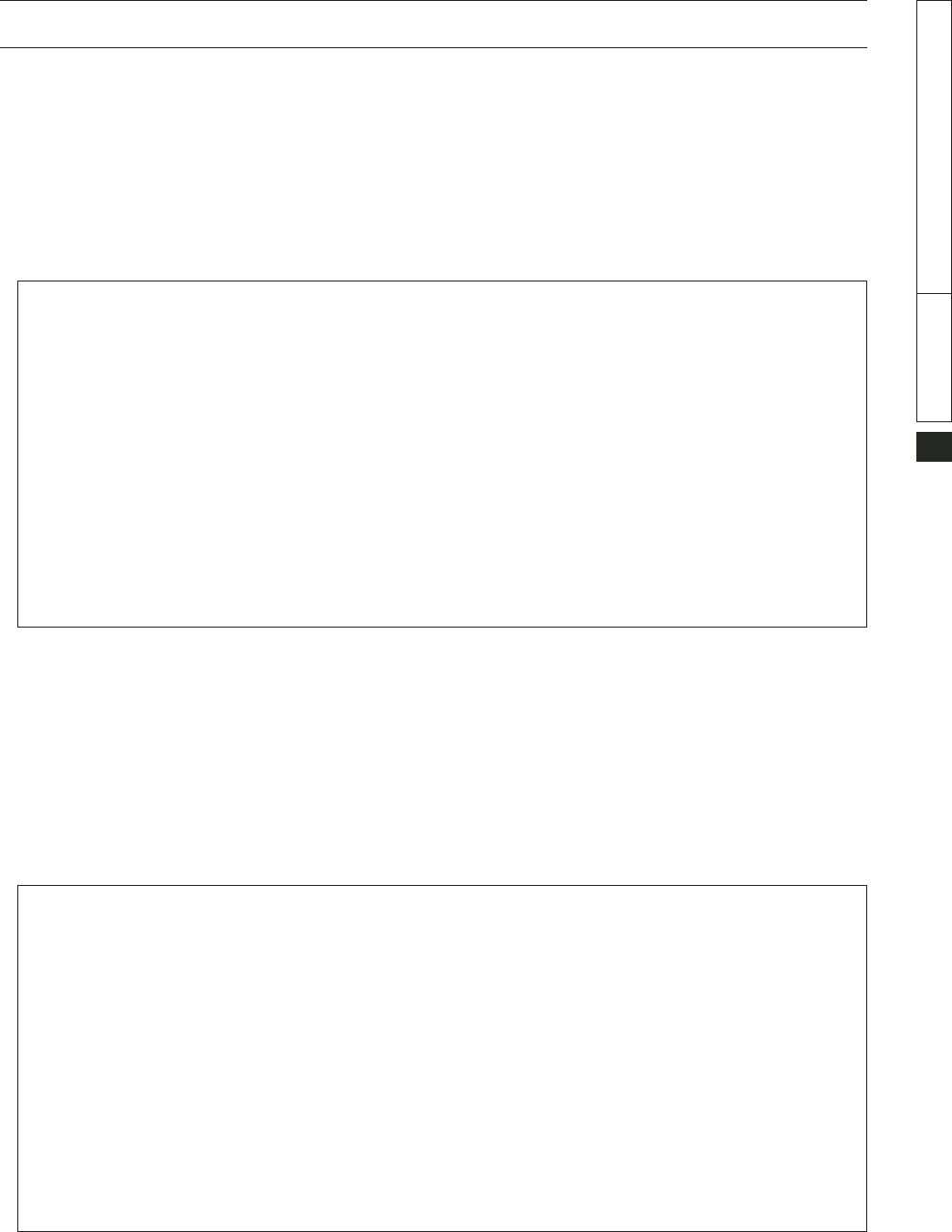

Butt Joint

This joint is the easiest and also the weakest. It is usually the first joint most of us make. You might see this

kind of joint in a bird house or feeder, because those items do not need extremely strong joints. Sometimes

the butt joint is reinforced by dowels or corner braces.

Examples of butt joints in woodworking:

16

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Mitre Joint

The mitre is a type of butt joint. The wood is cut at a precise angle using a mitre saw and mitre box.

It looks better than a butt joint and is a bit stronger. It can be tricky to clamp.

Picture frames and door frames often use this type of joint because it is a good way to join ornamental

wood. You will notice that picture frames are pinned or reinforced at the corners for extra support.

Examples of mitre joints in woodworking:

Rabbet Joint

This type of joint is often used for drawer fronts in cabinet work. A cut is made at the end of a board so it will

fit into another one.

Examples of rabbet joints in woodworking:

17

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Dado Joint

A dado joint is like a rabbet joint, except that the joint is made in the middle part of the board, not the end.

This is a strong joint, because there is a lot of surface contact. Dado joints are used to make slots for shelves

and other spots needing good support.

Examples of dado joints in woodworking:

Dowelled Joint

Pioneers used to make their own dowels to avoid having to buy nails. Dowels are hardwood pins that come

in a variety of sizes. Holes are drilled and lined up to fit dowels tightly.

A dowelled joint may be any joint that is reinforced with dowels (short, round pegs). Butt joints are the most

frequently dowelled joint. Most table legs are attached to the frame with dowels.

Examples of dowelled joints in woodworking:

Sometimes dowels snap off at a point of stress. (This is why people tell us not to tip our chairs.) The old

dowel has to be removed ( with a drill or careful chiselling), the hole cleaned and reglued. The replacement

dowel is sometimes a bit larger than the original.

The types of joints I like the appearance of:

The types of joints I appreciate for their strength:

The types of joints I am going to practice making:

18

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

19

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

POWER TOOLS

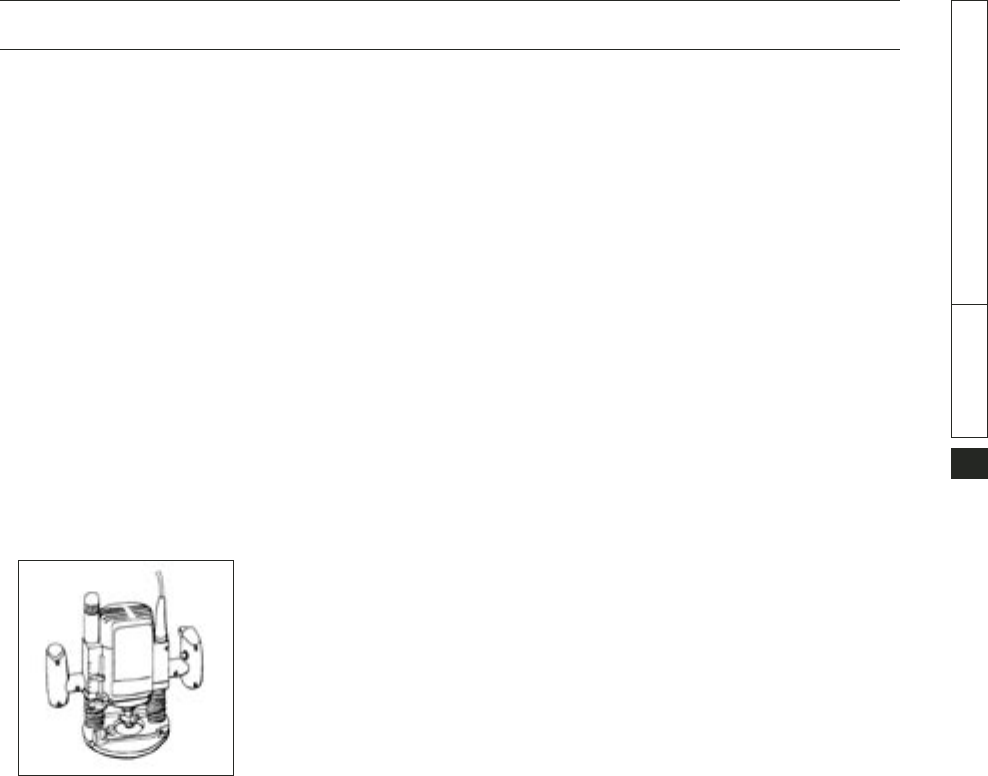

Router

This is a great tool that can accomplish all kinds of decorative and functional work. It is designed to cut

across and along wood edges. Examples of router work include table edges, signs, grooves and clean cut

holes.

Routers spin at speeds up to 24,000 revolutions per minute (RPM). Compare that to a drills 3,000 RPM! It is

very important to secure the bit before starting up the router.

As with any tool, do not force a router. Forcing a router can ruin the bit and damage the motor. Especially

when working with hard wood, it is often necessary to take more than one pass to remove the amount of

wood you want.

Routers use interchangeable bits so that you can make a variety of patterns in the wood. These bits are very

hard, very precise and usually very expensive! Cheap bits are just that. Cheap.

When choosing bits, think about all the uses you will have for that design. Most woodworkers start out with

the edge round and a straight bit.

Practice using a router with the bits available to you. Which patterns do you like? Which patterns would work

for your project?

Practice Using a Router – Name Plate

Materials

• always use eye or face protection

• a router and a straight bit, 2mm or 3mm

• wood, 2cm by 20cm by 50cm

• pencil

• clamp

• stencils (optional)

20

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Procedure

1. Check that the bit is secure and set to a 2mm or 3mm depth.

2. Print a name or word on the wood in letters so it suits the dimensions of the wood. You can

make a sign that says shop, office, keys, Grand Poobah or whatever you like. If you wish, use

stencils to outline the letters. Remember that the router will remove quite a bit of wood. Leave

space between each letter.

3.

Clamp the wood to a bench or place it in a vice with the top edge just above the vise edge.

4. Operating a heavy router is tiring. If you get tired, stop.

5. Hold the router over the board so that the bit is right over the first letter. The router should be

tilted so that edge touches the board.

6.

Start the router. Slowly lower the router into the letter space you want to dig out. Cut out

the outline of the letter first, then go back and clean out the insides. Some people like to just

outline the letters and not clean out the insides.

7.

Paint or stain your letters and the wood around them. One technique used by campgrounds is

to paint the letters one colour and paint the flat wood another colour with a roller.

Bandsaw

The bandsaw is an impressive stationary power tool. Its blade is a loop of steel with teeth on one edge. The

blade is driven and held in place by two large wheels. The wheels and most of the blade are covered by

metal shields. The blade runs through guides to keep it straight.

A bandsaw is something like a granddaddy jigsaw - it cuts straight or curved lines at a tremendous speed.

The blade cuts in a continuous downward stroke at a high speed. It cannot tell the difference between

fingers and wood, so watch your work!

To use the band saw, you push the wood slowly into the blade. Cut corners and tight turns slowly and

carefully. If you put too much stress on the blade it can break. One way to tell you are stressing the blade, is

that it starts to make a different sound. You can also smell the wood getting hot.

21

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Drill Press

A drill press is a large stationary tool that operates at high speed. You bring the drill bit down to the wood

with a downward pull of a lever. A drill press uses a variety of sizes of bits which need to be secured before

use. Ensure that the key is removed before turning on the drill.

To ensure that the drill bit goes completely through the wood, raise or lower the drill table accordingly, and

place a block of scrap wood under your project.

Always place a piece of scrap wood under your project. This protects the drill bit from hitting the table. It

also prevents splintering on the back of the wood you are drilling.

Safety Notes

1. Secure long hair. Do not wear loose clothes.

2. Before using the drill, always check to see that the last user removed the tightening key!

3. Hold the piece of wood you are working on securely. Otherwise, it might whirl around and

whack you.

22

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Stationary Belt Sander

The stationary belt sander is another versatile, powerful tool. Many stationary belt sanders also feature a disc

sander attached to the front. The disc is helpful for squaring ends and sides of wood pieces. As this is a high

speed machine, exercise great caution when using it. It can sand your fingers as fast as a piece of oak.

Use a stationary belt sander to square or round edges of wood parts. You can also shape smaller parts of

wood with this machine.

When pushing wood into the belt, push slowly so you do not overtax the machine. When putting pressure

on the belt, move the wood from side to side so the belt does not heat up or wear out on one spot.

23

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Radial Arm Saw

You will often see a radial arm saw on construction sites. It is used most often as a cut off saw (to cut wood

to certain lengths). Radial arm saws can make exact duplicates of a cut, which makes it a very popular saw.

The wood is held against the backstop with the left hand while the operator pulls the saw with the right hand.

To Use the Radial Arm Saw

1. Wear safety goggles or a safety face shield. Ear muffs are also a good idea.

2. Keep appendages away from the blade. Use a push stick to push wood past the blade.

3. Put your wood against the backstop so that the cut line lines up roughly with the blade. Do not

turn the saw on yet. Bring the saw blade down to touch the wood. Line the wood up so that the

blade will cut on the waste side of the cut line. This is usually to the right of the line.

4.

Slide the blade back. Hold the wood firmly. Turn the saw on. Draw the saw slowly and firmly

towards yourself.

5.

Turn off the saw. Admire the clean cut you have made with a radial arm saw.

24

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Table Saw

This is a machine for the serious woodworker. It features a smooth steel surface and a blade that can be

raised or lowered and tilted! On one side you will notice a rip fence which you use to cut boards to an exact

width. The blade has a protective guard.

The push through device is also a mitre gauge which you can use to move wood into the blade at a specific

angle. The angle can be set anywhere between 45 and 90 degrees.

The on/off switch should be in an easily accessible spot. The Off button is usually red. Always take note of

the position of the Off or Kill button or switch button before you use a machine.

Using a Table Saw

1. Always wear goggles or a safety face shield. Use of a table saw in 4-H assumes adult

supervision. Make sure sleeves are snug and not flapping.

2. If the table saw has a blade guard, use it.

3. Set the blade to a depth approximately 5 mm higher than the wood to be cut. Move the fence

out of the way.

4.

Set the mitre gauge to the cutting angle you want on the wood. Draw the gauge back so that

the wood can be set against it without the wood hitting the blade.

5.

Switch on the saw.

6. Hold the wood firmly against the mitre gauge with both hands. Slowly and steadily push the

wood through the blade.

7.

When the wood you are holding has passed the blade, slide it away from the blade and take it

off the table.

8.

Turn off the saw. Wait for the blade to stop before reaching for the cut part. It could touch the

blade and get fired back at you.

Source: Saskatchewan 4-H

25

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

CLAMPING & GLUING

Epoxy glue

You have used white and yellow glues for other projects. White and yellow glues harden due to evaporation.

When they harden, they shrink.

Epoxy glue does not shrink. Epoxy glue is a very strong glue that hardens due to chemical reaction. It is

more expensive, so is used only when the project calls for it, such as joints where there are gaps. Epoxy

glue fills up the gaps and then hardens to a very strong fi

nish.

To use epoxy glue, it is necessary to mix two components together. Each glue will have its specific

instructions on the container. Read them carefully and follow them completely.

When gluing wood, it is important that the wood be the same moisture content that it will be at time of use.

How to Glue

• select the appropriate glue

• prepare the project

• have the wood at the same approximate moisture level that it will be at time of use

• make sure all surfaces to be glued are clean and dry

• think through how you are going to clamp the project before applying the glue!

• have all the necessary equipment available

• apply glue to one or both surfaces (according to instructions)

• apply steady and uniform pressure with clamps

• wipe off excess glue

• allow glue to dry before removing clamps

• let the excess moisture at the joints (from the glue) evaporate before further machining. Let

joints dry for several days.

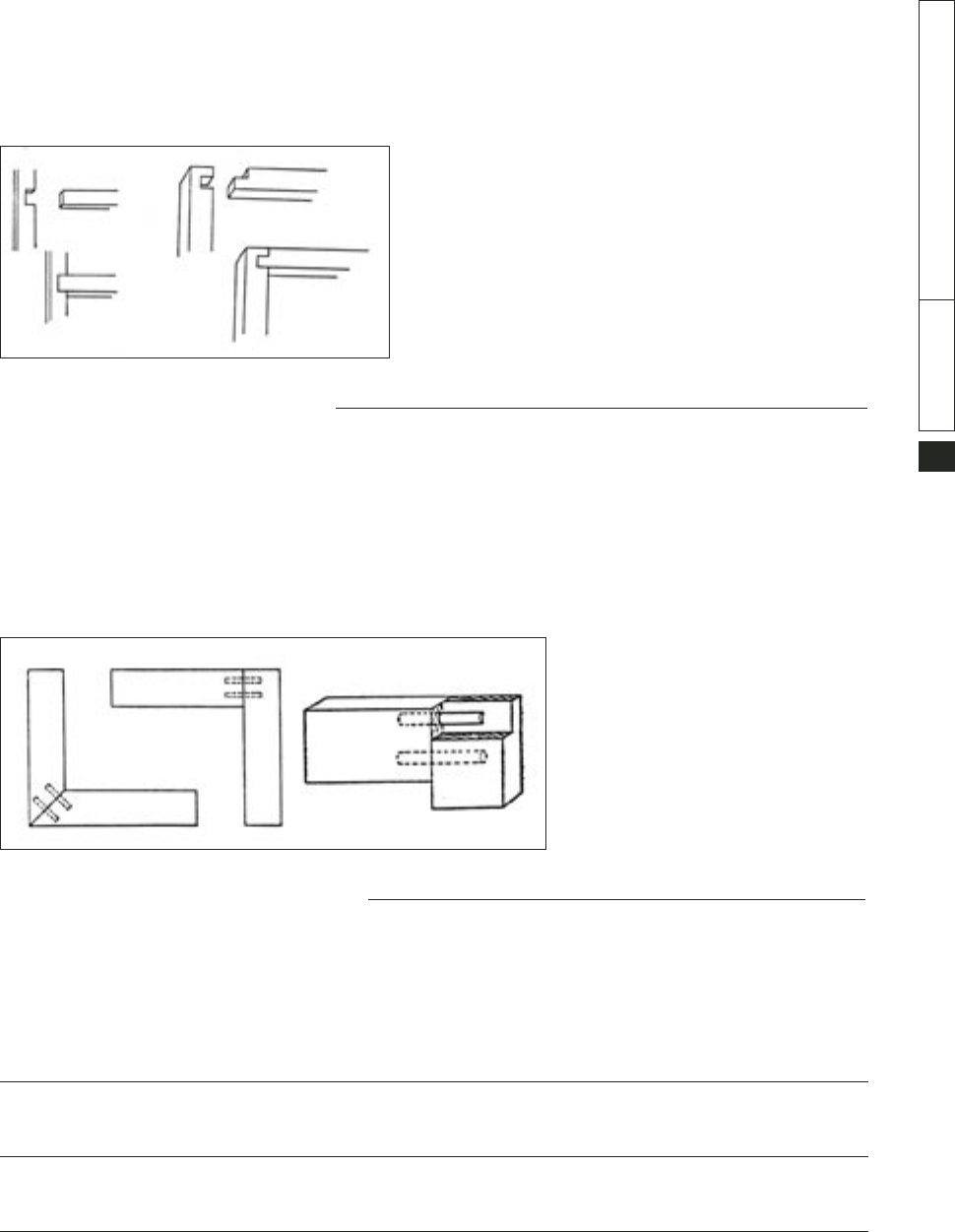

Using Dowels

Dowels are used to fasten pieces of wood together and to strengthen joints. Dowels can be cut from dowel

rods or purchased by the piece.

Dowel holes are cut with a drill press or with a hand drill, guided by a doweling jig.

What Diameter of Dowel? You should be able to insert the dry dowel into the dowel hole easily by hand. If it

were too tight, the glue would be rubbed off as the dowel was inserted.

What Length of Dowel? Dowels are usually cut 1/4 inch shorter than the combined length of the two dowel

holes. When you press the two pieces of wood together on the dowel, you do not want the dowel holding

them apart!

26

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

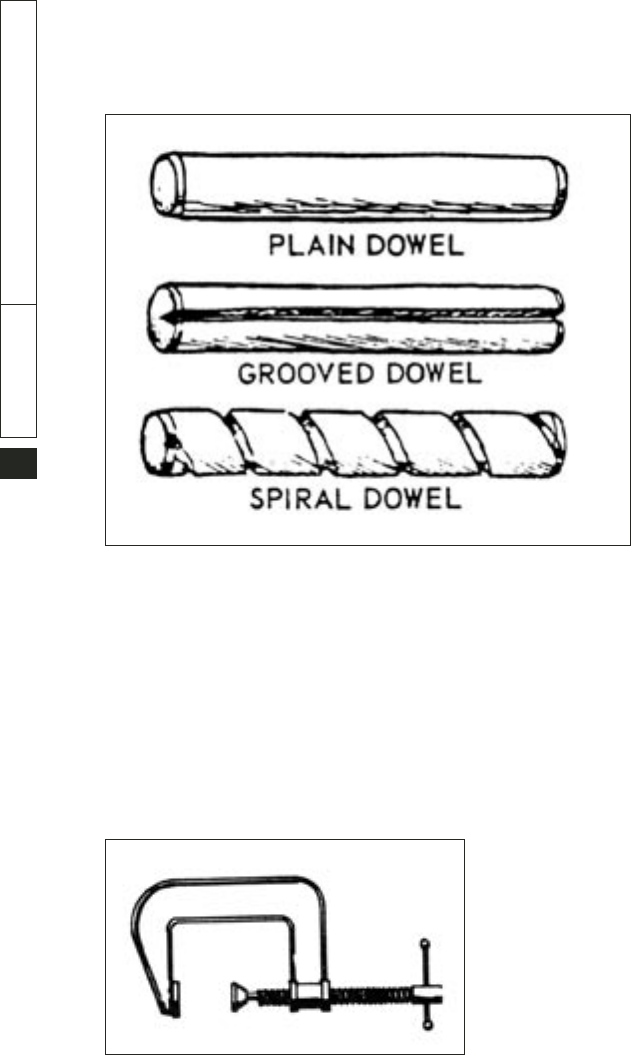

What type of dowel? Choose between a plain dowel, a dowel with a longitudinal groove or a spiral grooved

dowel. The grooves help the air trapped in the hole to escape and can help the glue to spread inside the

hole, making for a stronger joint.

Do a dry run with the dowels in your project before applying glue!

Types of Clamps

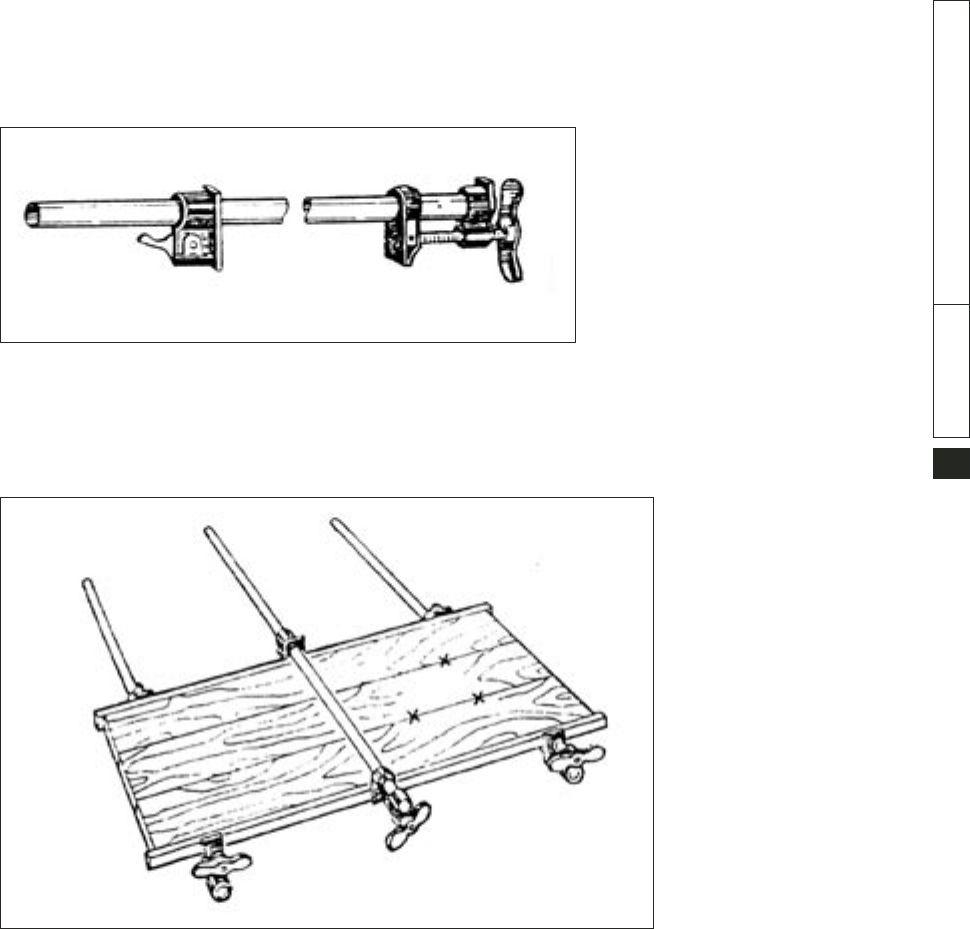

C-Clamps

These are small c-shaped items which are used to hold two boards together for boring holes, gluing or

making a saw guide. Tighten the screw to increase pressure. To prevent dents in the wood, put a piece of

scrap wood between the clamp and the good wood.

Handscrew Clamps

These clamps have two long parallel bolts which are adjusted separately. They are used for jobs that are too

big for C-clamps. To adjust the pressure, screw the bolts in opposite directions.

27

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Pipe Bar Clamps

These clamps come in a range of lengths. Adjust the clamp to fit the project by moving the adjustable stop

back and forth along the bar. Increase pressure by turning the crank screw.

Adjustable Bar Clamp

This also called a cabinet clamp. It adjusts by turning the handle and can be used for the same purposed as

the pipe bar clamp.

Clamping Tips

• keep clamps clean or you will be pressing grease and dirt into the wood fibres.

• protect wood surfaces by putting a piece of felt or scrap wood under the clamp

• use a piece of styrofoam against an irregular piece of wood when clamping. It will press into

and hold the wood without marring.

•

try pieces of inner tube as clamps for irregular pieces of wood

28

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

29

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

ADDITIONAL HAND TOOLS

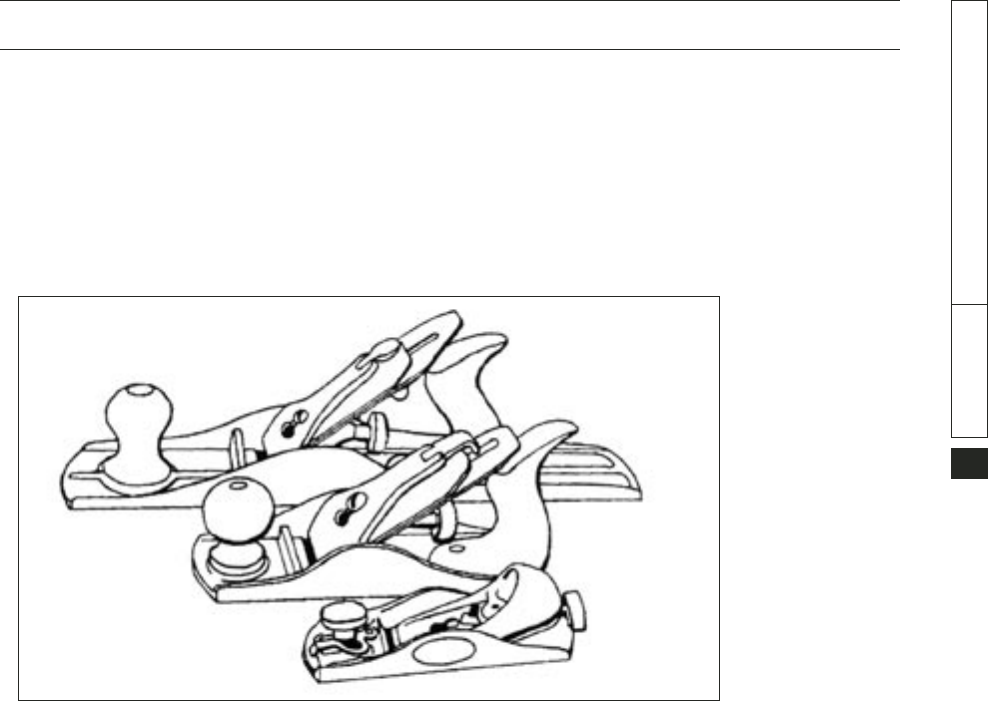

Planes

Woodworkers use planes to smooth wood surfaces to reduce or eliminate the need for sanding. Sounds

good to me!

•

Plane with the grain, not against it or you will raise splinters.

• Always set a plane down on its side. This protects the blade.

• Make or buy a fabric sock for storing your plane.

There are many kinds of planes available. Here are the most commonly used ones.

Block Planes

The smallest and most practical plane for young woodworkers, the block plane is about 12 cm long. It is

small enough to be carried in a tool box. It works well to finish work. It has a low blade angle and is often

used for fine work or cutting across end grain.

It is important that planes be in proper adjustment, or they do not do a proper job. Turn the plane over

and check along the bottom. The blade should appear through the gap evenly, about the thickness of a

sheet of paper.

To push the plane iron out (to get more blade exposed) turn the adjusting knob clockwise. To pull the iron in,

turn the knob to the left until the blade is in the correct position. Then turn it clockwise until it starts to push

the plane out. The plane iron will stay in the right place when the plane is used.

To adjust for an even blade, loosen the lever cap screw. Turn the plane over and look at it. Press the plane

iron to the right or left until it is even. Then tighten the lever cap screw.

Test the plane on a piece of scrap wood, not your project.

Smooth Plane

This is also a short plane, in sizes from 12 to 25 cm long. It cuts extremely smooth surfaces and stays adjusted.

The smooth plane can also be used for rough planing, planing end grain, chamfers and edge shaping.

30

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Jack Plane

This is a medium sized plane, from 30 to 75cm long, which can be used for just about any job! Because it

has a longer bottom, it does less riding up and down on uneven surfaces and quickly cuts off the high spots.

Fore Plane and Jointer Plane

These planes do a good job on cutting an edge or surface perfectly straight. Fore planes are usually 45 cm

long and jointer planes are usually 45 cm to 60cm long. Their long lengths allow them to ride over bumps

and produce a smoothly cut surface.

31

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

SHARPENING TOOLS

Do this with adult supervision.

Whetting

Whet your chisels and plane irons on an oil stone to keep a very sharp cutting edge.

Apply oil to the stone surface to keep it moist. The oil prevent particles of steel from clogging the pores of

the stone. Wipe the stone before putting it away.

Hold the chisel or plane iron on the fi

ne grit oil stone with the bevel flat on the surface. Raise the handle

slightly (5 degrees or less) so you whet only the forward part of the bevel.

Move the chisel or plane in a circular pattern back and forth lengthwise on the stone several times. Working

in this way wears the stone evenly so it will last you all your life.

After you have sharpened the bevel edge, turn the blade over to remove the little bits that have appeared on

the other side. Lay the blade fl

at on the stone. Move it back and forth a few times to remove those little bits.

Inspect the blade edge. Is it completely and evenly sharpened? Are there still some nicks or unsharpened

spots? It may be necessary to repeat the whetting process until you have done a complete job.

Test your blade on a piece of wood (not your project!).

Plane marks show less if the corners of the plane iron are slightly rounded.

Round off the corners by slight honing on the whet stone.

When is it time to grind? When you notice the cutting edge is nicked or it is getting harder and harder to use

the tool, it is time to grind.

Use a grind stone or an emery stone for this job. Your leader or another adult will demonstrate this.

Wear eye protection! Dip the blade in water frequently so it does not over heat. You may want to hold the

blade in a clamp to hold it steady while grinding.

The plane iron or chisel should be ground to a 25 or 30 degree angle. This provides the right combination of

sharpness and strength.

After grinding fi

nish by whetting on the oil stone for a very sharp cutting edge.

32

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

33

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

WOODWORKING TIPS

• If you store your tools on a pegboard, paint the shape of the tool on the board, to help tools

make their way back to the right spot!

•

Magnetic strips on the workbench or on the wall nearby hold small metal tools in sight.

• Fight scratches and rust on hand tools. Store them in a drawer on a piece of carpet which has

been sprayed with light machine oil.

•

Help your tape measure slide smoothly! Rub it with a bit of paste wax.

• When buying a tool with a wooden handle, examine the direction of the grain of the wood.

Wood grain that runs parallel to the tool head is strongest.

•

A bit of beeswax or paraffin on the tip of a nail will aid in driving a nail into hardwood.

• Don’t want to hit your thumb when starting a nail? Hold the nail with a pair of pliers, or else

push it through a piece of cardboard or stiff paper!

•

Protect the teeth on your handsaw. Slide it into a slit piece of old garden hose or a piece of

styrofoam.

•

Store and transport your wood chisels with their points in an old soft ball. Tennis balls work well

for this.

•

Does your saw blade get stuck in the kerf when sawing long pieces of wood? Prevent this by

sticking a small wooden shim into the kerf after you have started the cut.

•

Only use one measuring tape for a project. Sometimes the end hooks vary as much as 1/16

inch. If you must use more than one measuring tape, check them to ensure they give the same

measurement.

•

For precise measurements with a measuring tape, start measuring at the one cm. or one inch

mark on the tape. (Sometimes the end hook has a bit of play in it.)

•

To check for square in a project, measure the diagonals of the piece. They should measure

exactly the same.

•

Making many pieces of the same item? Use only one piece as the pattern.

• You can copy a pattern using a photocopy and an iron! Copy the picture you want. Turn

the page, print down, onto the wood. Tape it so it will not shift. Heat it with an iron. Check

occasionally to make sure the pattern is clear in all areas. If the pattern has words on it, first

print it onto tissue paper, then turn that copy over and copy it. You will produce a copy that has

the words backwards on it.

•

Use old inner tubes as clamps. They will apply gentle but firm pressure onto odd shaped

projects.

•

Are your C clamps leaving marks on projects? Pad the clamping surfaces with felt, chair leg

protectors, the caps from film canisters or small pieces of wood.

• Store glue bottles upside down, with the caps on securely! Store in a can or else make a simple

holder similar to a toothbrush holder.

•

Save those old toothbrushes! They work well to clean out dust or to apply stain in small areas.

• A little too heavy with the hammer? Made a few too many dents? Lift the dent by ironing a

moist cloth over the dent. (Wood cells swell with the addition of water.)

•

Hands all splattered with oil-based paint or stain? Soften the paint with salad oil! Then, wash

with warm soap and water.

•

To prevent dents from those last hammer taps, put an old tennis ball over the head of the

hammer.

•

Use clothes pins as mini clamps for tiny pieces of wood.

• If you lose the lid from your glue bottle, or the original one does not work well, try a mariette

(the electrical wire nuts you use to twist two or more electrical wires together). The thread

should hold on snugly.

•

Never saw freehand. Take the time to draw a straight line!

• Put a piece of scrap wood under your project when you are drilling holes in it. This will prevent

you drilling holes into the work surface.

•

Always saw on the waste side of the marking line.

• Clean as you go.

34

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

• Do you plan to stain your project? Stain it before filling the nail holes, to prevent residue

blemishes on the wood.

•

Stain soaks deeply into end grain and makes it darker than face grain. To better match the stain,

sand the end grain with a higher grit sandpaper than the face grain.

•

Prevent rounding of edges by a power sander by putting another board the same thickness

up against the board you are sanding. The sander will ride straight over the edge, rather than

around it.

•

Try styrofoam to clamp irregular shapes. The styrofoam will conform to the shape of the piece

and hug it snugly without scratching.

•

Hammer head slipping? Rough up the surface with a coarse emery cloth, a file or an abrasive

wheel.

•

Do you keep dropping screws when starting them? Try:

1. Chewing gum on the head (the screw’s head, not yours!)

2. Rubber cement on the head.

3. A short piece of rubber hose on the tip of the screwdriver that is slightly bigger than the

head of the screw.

• Save some sawdust from your project to make perfectly matched wood putty. Mix the dust with

white glue.

•

Do your safety goggles fog up? After cleaning and drying them, put one drop of dish detergent

on them and wipe dry.

•

When using tools, focus on the job. If you need to talk to someone, stop work first.

• Avoid startling someone who is using tools or power equipment. Approach from the front,

slowly, if possible. (Kind of like approaching a horse!)

•

Never force a machine.

• Ask your leader to show you how to check to see if a machine or tool is properly grounded.

• To prevent bubbles, do not shake topcoats. Stir them gently.

• Make your own tack cloths! Moisten cheesecloth in mineral spirits. Add a teaspoon of any

topcoat material (e.g. varnish) to the cheesecloth and knead it until the topcoat material is

absorbed evenly. Store in a closed glass jar.

•

When planing hard wood, follow the grain.

• Practice new skills on scrap wood first!

• A surface that you are going to glue should be clean and free of dust, but not sanded. Wood

glues best soon after it is cut.

35

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

THINGS TO MAKE

1. Tray

2. Shadow Box

3. Chess Set

4. Paddle full size or for display only

5. Picture or Mirror Frame

6. Date Cubes

7. Set of Wooden Letters

8. Turtle Box

36

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

37

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Tray

Make this as a practical item or decorate it to add colour to your home! This tray features rabbeted corners

and a dadoed bottom for strength and appearance. Select a washable finish. The dimensions are for a

standard tray. Adjust them for your needs. Optional hand holes can be cut to size.

The next time you make this tray, you could try another type of joint.

A simpler version of this tray can be made with butt joints, gluing and using fine screws to secure.

Cut List

1 1/4” x 20” by 13” of plywood (tray bottom)

2 2” x 2” x 20” sides (Wood of your choice)

2 2” x 3” x 12” ends (Wood of your choice)

Instructions

As with all projects, it is suggested that you sketch or make a cardboard model of this project first, before

making it in wood.

1.

Measure, mark and cut the pieces of wood.

2. Test assemble the pieces to check for fit.

3. Insert a 1/4” dado blade in the table saw. Set it to cut a groove 1/4” deep. Test a scrap of the

wood you are using for the tray bottom in this groove. When this fits smoothly, dado the ends

and sides of the tray bottom.

4.

Test assemble the tray.

5. If you want to have hand holes in the ends of the tray, sketch and cut them now. Sand them

smoothly.

6.

Sand all the parts of the tray.

7. Glue, assemble and clamp.

8. Finish as desired.

9. Take a picture for your record book!

38

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

39

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

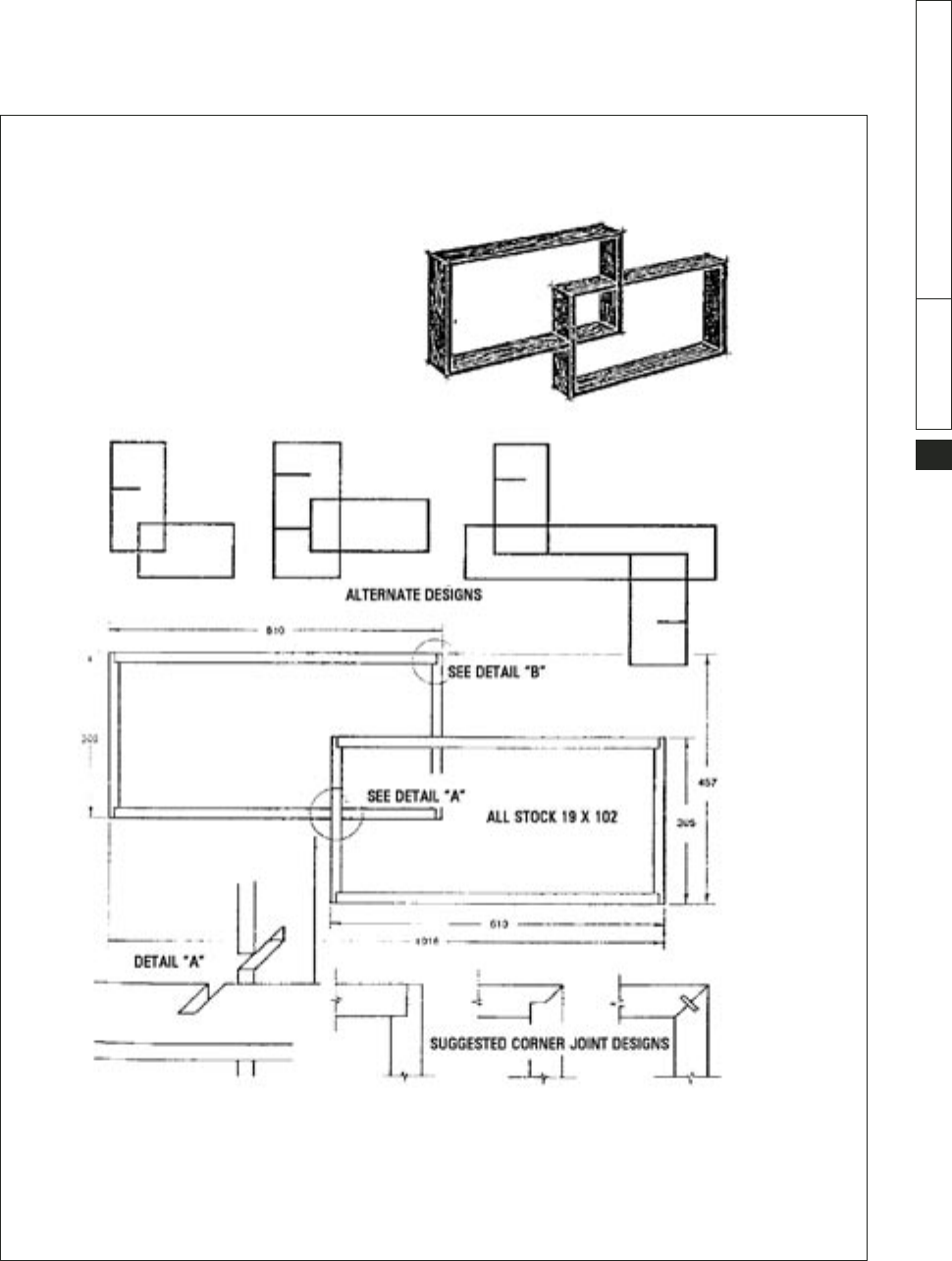

Shadow Box

Use this to display pictures or collections of small items. Use the type of corner joint you prefer. Or make

several shadow boxes, each with a different style of joint.

40

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

41

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

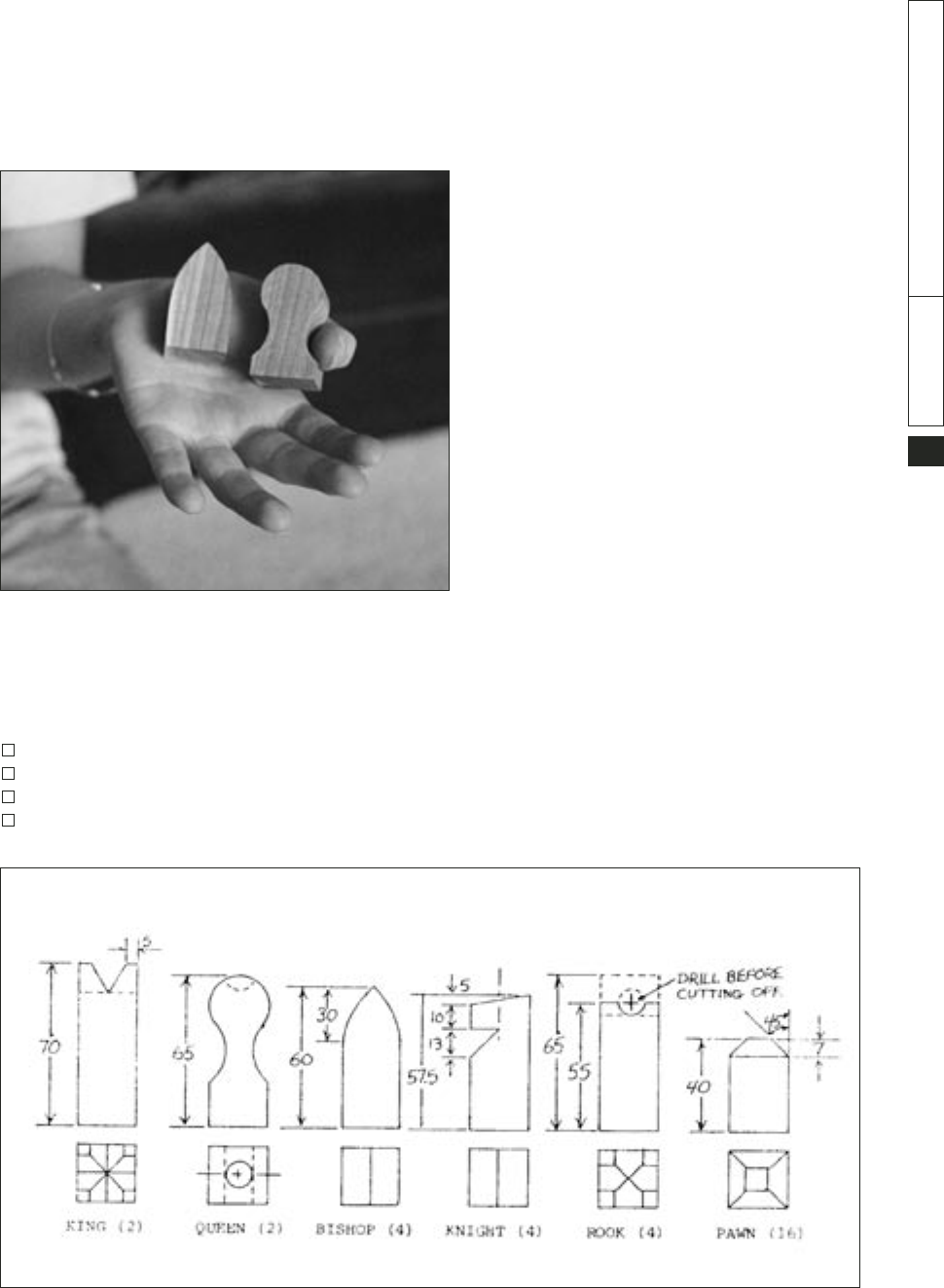

Chess Set

Make one for a special gift or one for yourself! A challenging project.

The designs for the chess pieces can easily be modified or replaced with styles you prefer. The traditional

sizes for the pieces descend in this order: king, queen, bishop, knight, rook, pawn.

If you have only one colour of wood, stain half of it to provide the colour contrast needed for the two armies

of pieces.

Materials for the Chess Figures

green felt

Hardwood

Dark 950mm x 25mm x 25mm

Light 950mm x 25mm x 25m

42

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Tools

pencil

sanding disc

ruler

pencil

try square

marking guage

tenon saw

file

chisel

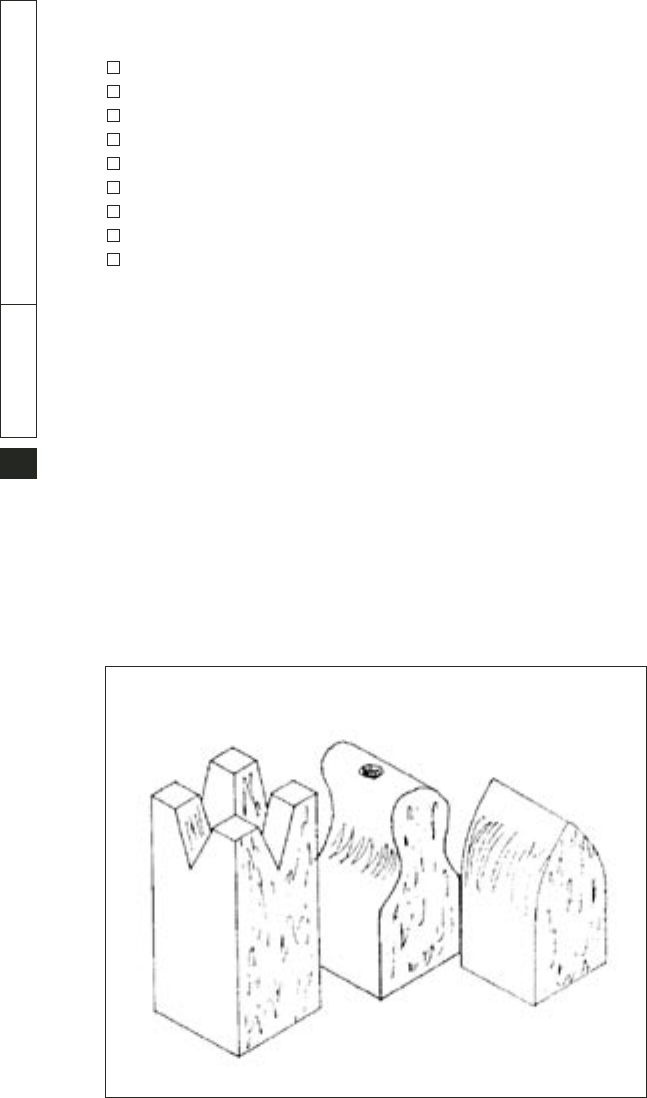

Instructions

1. Mark and cut out the 16 pieces from the light wood and from the dark wood.

2. Use a sanding disc to trim the pieces to the exact length.

3. Mark out the desired design on the pieces, using a ruler, pencil, try square and marking gauge.

4. Cut with a tenon saw.

5. Shape and tidy up the cuts with a file and firmer chisel.

6. Use a sanding disc and belt sander where possible to assist in the shaping.

7. Do final sanding with glasspaper.

8. Varnish the pieces.

9. Glue green felt to the bottom of the pieces, so they do not scratch the board.

43

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

The Chess Board

Materials

4 strips of white wood for the board 15mm x 35mm x 350mm

4 strips of dark wood for the board 15mm x 35mm x 350mm

4 strips for frame 10mm x 25mm x 350mm

Tools

measuring tools

plane

marking gauge

table saw

sandpapers

nails

nail set

paste wax

Instructions

Phase One

1. The strips are longer than the finished board, to allow for error and sanding

2. Lay the strips for the board side by side, alternating dark and light woods. Watch the direction

of grains, so the pattern will be most pleasing.

44

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

3. Glue the inside edges of each strip and clamp tightly, using pipe clamps. Make sure all pieces

remain level and even at one end. If you notice them buckling, unclamp, fl

atten them down,

then reclamp. Do not rush this stage!

4.

Allow to dry for 24 hours.

Phase Two

1. Recut the board into 35mm strips, across the coloured strips of glued wood.

2. Lay the strips out in a chess board pattern. Match the corners perfectly.

3. Glue and clamp.

4. Allow to dry for 24 hours.

Phase Three

1. Plane one side flat and smooth. Do not remove any more wood than is necessary.

2. Mark the board to thickness using a marking gauge.

3. Plane the board to thickness.

4. Plane the edges smooth and 90 degrees to the best side.

5. Measure board to length (check the numbers of squares required!).

6. After triple checking, cut off the extra length of board.

7. Sand all sides and edges flat and smooth using increasingly finer grades of sandpaper.

8. Measure and cut your frame strips.

9. Fit frame strips to the board using mitred corners.

10. Nail the frame to the board. Set and fill the nail holes.

11. Sand all surfaces.

12. Varnish. Let dry 24 hours.

13. Sand with 400 wet/dry sandpaper.

14. Apply second coat of varnish.

15. Sand lightly with 400 wet/dry sandpaper.

16. Apply two coats of paste wax allow 20 minutes between coats. Polish.

17. Invite someone over for a game of chess!

45

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Paddle

You can make this project from hardwood or softwood. With hardwoods, you will be able to achieve a

thinner blade. Woods that work well for a paddle include spruce, cherry, maple, pine, butternut and ash.

Some people like to use a combination of woods in a paddle, especially if it is to be displayed.

The correct size for a personal paddle? If you can rest your chin on it while standing, it is the correct length

for you. The instructions given are for a generic paddle, made of fir. This paddle is good for both lake and

river use. The Lee Valley Tools web site gives instructions on making a marking jig which helps in marking

the shape you would like in your paddle shaft. Visit www.leevalley.com.

Materials

1 30mm x 30mm x 1500mm

4 20mm x 20mm x 550mm

4 20mm x 15mm x 450mm

2 30mm x 30mm x 100mm

waterproof glue (titebond II)

sandpaper

marine varnish or urethane

Tools

table saw

jigsaw

rasps

clamps

planes

46

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Instructions

1. Make sure that the main shaft piece (the longest one) is straight, true and without flaws.

2. Glue 2 – 20mm x 20mm x 550mm pieces directly onto each side of the main shaft with ends

flush. Clamp well and let dry.

3. Glue 2 – 15mm x 20mm x 450mm to the sides of the pieces you glued on in step 2. Clamp and

let dry.

4.

Glue the 2 – 30mm x 30mm x 100mm pieces to opposite sides of the handle end of the paddle.

Clamp and let dry.

5.

Pencil the outline of the blade shape on the paddle. Pencil the desired handle shape on the

handle. If you already have a paddle you like, you could use it as a pattern.

6.

Bandsaw or jigsaw the shape.

7. Using rasps and planes, shape and taper the blade to about 8mm on the edges and tip. The

middle of the blade should remain a bit thicker, about 12mm (for strength). The blade should

thicken a bit as it reaches the shaft.

8.

Round the shaft until it feels comfortable in your hands.

9. Shape and taper the handle so it comfortably fits your hand. A bad fit to your hand can cause

blisters. Blisters are not fun on a canoe trip.

10.

Sand smooth. Remove dust. If you wish, you can put some kind of identification mark somewhere on

your paddle at this time (initials, phone number etc. It’s optional, but a good idea.)

11.

Apply three coats of marine varnish or urethane.

12. Ask someone to take a picture of you with your new paddle. Congratulations! Long may your

paddle sing.

Alternative

You may also paint the paddle with exterior grade paint. You can also paint or burn a design into the paddle,

then varnish over it for protection.

47

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

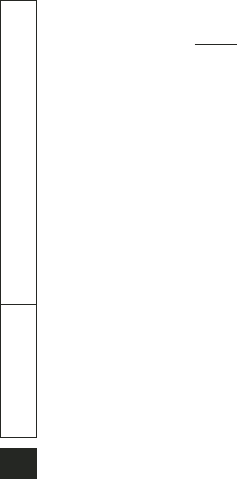

Picture or Mirror Frame

You can make this to any dimensions, of course. Varnish the frame, if you wish to show off the grain. Paint

it, if you want to emphasize what the frame will hold. Or leave it unfinished, if you are using a material such

as old barn board! The choice is yours.

Materials

wood of your choice

glue

thin panel pins (optional)

glass or mirror cut to fit (have this cut after you have made the frame!)

matting for picture (optional, but recommended)

small screws and wire for hanging

small scraps of felt

Tools

mitre box and saw

router

sander

saw

Cut List

2 1 3/4” x 1 3/4” x 18” (sides)

2 1 3/4” x 1 3/4” x 16” (top and bottom)

1 piece of thin board to fit within the finished back (measure and cut to fit finished frame)

Instructions to make a 18” by 16” frame.

1. Cut wood, using a mitre saw and box. Cut at a 45 degree angle. Take great care to avoid splinters.

2. Test assemble the pieces, to make sure everything will fit together snugly.

3. On the back side of each piece, rout out a groove on the inside of each piece. This will form a

ledge that the picture or mirror will rest on.

48

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

If you are routing hard wood, it may take more than one pass to make the depth of ledge you

want. Do not force your router.

4.

Glue and clamp the four pieces together. Lay on a flat surface. Let dry overnight. It might be

a good idea to put a clean piece of paper or cardboard over top, with a bit of weight, to hold

things flat as they dry.

5.

If you want extra reinforcement, use very thin panel pins to nail the pieces together.

6. Have the glass or mirror cut now to fit the finished product. Insert the glass or mirror into the

frame. Secure it with fine panel pins.

7. Attach picture wire frame between small screws.

8. Glue small pieces of felt to bottom corner of frame so it will not mar the wall.

Tip: To avoid tilting pictures, hang frames from two, not single hooks on the wall.

49

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Date Cubes

This project requires you to make two identical cubes from hardwood. With only two cubes you will be able

to display all the days of the month. This project calls for a steady hand with a router. You can make the

cubes with scraps of hardwood.

Materials

enough hardwood to make two cubes the size that you want

glue

Tools

table saw

square

measuring tools

hobby knife or carbon paper to transfer patterns

pencil

disc sander

sandpaper

clamps

router

if starting with rough lumber, you will need access to a joiner or a planer

patterns for numbers

Instructions

1. First, practice on scrap wood making numbers using the router tip you plan to use for the numbers. This

step will help you decide how big you should make your cubes. Anything smaller than two inches would

be very diffi

cult to work with, or to read.

2. If you are starting with rough lumber, smooth it so that it will glue together perfectly.

3. Measure, cut, glue and clamp your two cubes of hardwood. Take care to line up the grain in a way that

you find pleasing.

4. Use the disc sander to smooth all surfaces. Make sure that all sides are square to each other and have

the same dimension.

5.

Print a style of number that you like (the simpler the better for a first try) using a computer. Trace or cut

the pattern into the wood. The cut outline of the numbers will guide you when you are routing.

6.

On one cube you will rout these numbers : 0, 1, 2, 3, 4, 5. On the other cube, make these numbers: 0, 1,

2, 6, 7, 8. (One “6” will serve also as a “9”.)

7.

Sand the routed cubes, using increasingly finer sandpapers. Finish with your preferred finishes.

8. Take a picture for your record book! Congratulations!

The numbers on the cubes can also be painted or burned in using wood burning tools.

50

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

51

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Wooden Letters

This is a good way to practice using a band saw, jigsaw or scroll saw. You could make a set of letters as

a gift for a child, for a local school or Sunday School. You could also make separate letters that spell out a

name or messages, which could be used at home or on a shelf at school or at a Seniors’ Centre. E.g. Happy

Birthday! Joy! Congratulations! Welcome! Etc.

Materials

plywood or hardwood (how thick will the wood need to be, so that the letters will stand up easily?)

paint or stain – if these are to be used by a young child, select a child safe finish

patterns for letters

Tools

band saw or jig saw or scroll saw

sandpaper

paintbrush

ruler

Instructions

1. Mark the letters you are going to cut out on the wood, using either a pattern or by drawing

freehand.

2.

Cut out the letters. With letters that have an interior opening drill a hole first, then use an

appropriate saw.

3.

Sand carefully, working to avoid splintering the wood.

4. Finish, using a child-friendly paint.

5. Take a picture for your record book or e-mail it to us! Congratulations!

52

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

53

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Business Card Holder

Makes a great gift. Also a great item for bazaars or fundraisers! Very simple, useful item which requires

careful use of band saw, orbital sander and router. It uses up those scraps of hardwood!

This would be a very nice thank you gift for sponsors, guest speakers or judges!

Make one long holder, rout the channel out, then cut to desired width. If you try to make just one, it is too

tricky to rout out the channel.

Materials

1 scrap of hardwood, 1” thick

finishing supplies

sandpaper

Tools

Band saw

Router

Instructions

1. Cut a strip of hardwood about 2” wide and slightly longer than three business cards are wide.

2. Secure the wood. Using a 1/2” bit, cut a 2” deep channel in the top. The business cards will sit

in this channel.

3.

Sand and finish.

54

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

55

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

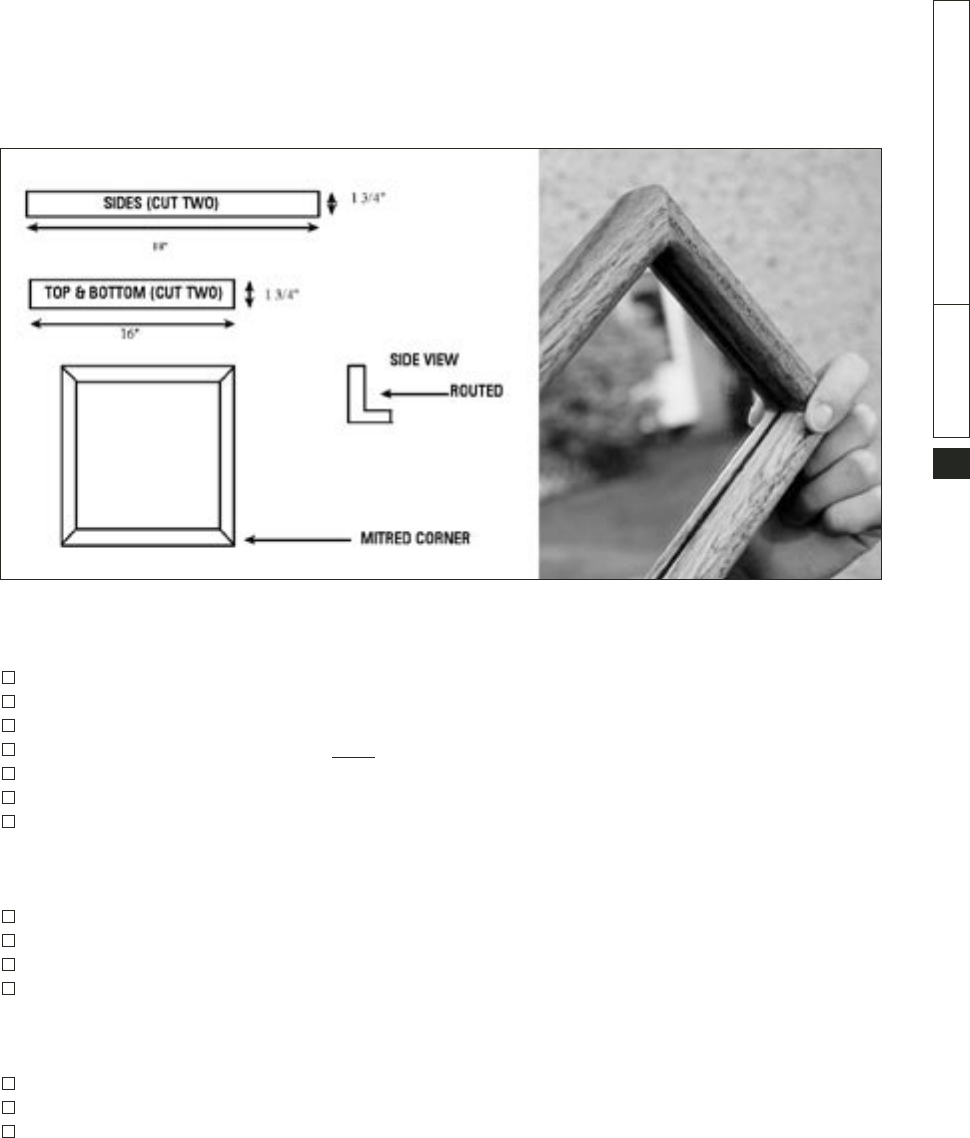

Turtle Box

This is a clever container made of a 2” x 4”!

Materials

1 2 x 4 x 24”

glue

sandpaper

varnish or other finish of your choice

Tools

joiner or planer

clamps

band or scroll saw

pencil

disc sander

Instructions

1. Run the 2 x 4 through the joiner or planer to get completely smooth surfaces.

2. Cut the 2x4 into three equal lengths (approximately 8” each).

3. Glue one piece of 2 x 4 on top of another. Clamp and let dry.

4. Glue the third piece of 2 x 4 to the top of the other two. Clamp and let dry.

5. Draw the pattern of the turtle on the top of the glued wood (on the side with no seams).

6. Use a band saw or scroll saw to cut out the turtle.

7. Cut a 1/4” layer of turtle off both sides. You will have two thin turtle shapes and one thick one.

8. Trace the drawer pattern on the thick turtle.

9. Use the band saw to cut out the drawer.

10. Use the band saw to cut a 1/4” layer off both sides of the drawer. You will end up with two thin

drawer pieces and one thick one.

56

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

11. Trace the drawer cavity on the thick piece of drawer.

12. Use the band saw to cut out the drawer cavity out of the thick piece of drawer.

13. Glue the thin drawer pieces to the thick drawer piece, to make a complete drawer! Test to

make sure it will go into the turtle. Clamp and let dry.

14.

Glue the thin turtle pieces to the thick turtle pieces to make a turtle. Clamp and let dry.

15. Sand to remove all traces of glue and to smooth the surfaces.

16. Stain and varnish the way you would like.

17. Take a picture for your record book!

57

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

MEMBERS: I CAN CHECKLIST

Leader Signature

Safety

Meet all safety objective of levels one and two

Identify and deal appropriately with shop hazards - physical,

mechanical, chemical, electrical and human

Encourage safe behaviour in other people

Show leadership by working and playing safely

Teach safe procedures to other members

Select personal protective devices according to task at hand

Determine if safety shields are in place by visual inspection

Locate shut offs for power tools

Operate shut offs

The Forestry Industry

Identify forestry as one of Alberta’s major industries and employers

Trace the route of wood products from wood lot to consumer

Name at least five careers linked to forestry and the preparation for that career

List sources of information on the forestry industry

Drafting, Drawing & Dimensioning

Produce, read and interpret isometric and orthographic drawings

Translate drawings into projects

Identify/determine degree of difficulty of a project from a drawing

Plan order of work from a drawing

Plan layout of pattern on wood, to get best use of wood

Label drawing accurately and clearly according to standard woodworking procedures

Take accurate measurements

58

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Joinery

Identify at least three different joints and explain how they are made

Identify tools used for specific joints

Construct a project using a new type of joint

Select jointing techniques according to strength, appearance

Glue and clamp a joint for maximum strength and best appearance

Super Power Tools

May include the following: Router, Band Saw, Radial Arm Saw, Drill Press,

Stationery Belt Sander, Bench Grinder, Table Saw.

Identify tools accurately

Explain purpose of each tool

Explain and demonstrate the use of each tool

Explain safety precautions for each tool

Compare various models

Demonstrate safe use of tools

Ask for help if unsure

Ask another member to stop if I see unsafe practices or hazards.

Gluing & Clamping

Identify at least three types of clamps

Demonstrate how to use those clamps

Show how to avoid clamping scars on a project

Determine the correct amount of pressure when clamping a glued joint

Name three types of glue used in woodworking, their respective

properties and the best use of each

59

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

Additional Hand Tools

Identify block plane and jack plane and demonstrate their use

Demonstrate inspection and care of a plane

Assess need for blade adjustment

Accurately and safely set the blade in a plane

Use a plane to smooth wood

Explain the value of maintaining tools in good order

Sharpening Tools

Determine when a tool needs to be sharpened

Name the equipment and supplies to be used in sharpening

Observe safe procedures when sharpening tools

Sharpen chisels and plane irons

Test for the quality of a sharpening job

Explain how to use and store tools to prevent damage and excessive wear

Explain dressing of a grindstone - what, why, how and when

60

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

61

ALB E RTA 4- H WO O D WO RK ING P ROJE CT LE V EL T H REE

EVALUATION

Your input is a valuable asset to the 4-H program!

As you go through the project year, write your comments and suggestions about the project on this form.

When you complete your project, mail this form to us. We want to hear from you!

Woodworking Project Evaluation

Evaluation Date:

Please Tell Us

Which techniques and skills did you learn and use for this project?

What did you like best about completing this project?

Are you pleased with your project? Is there anything you would change if you were to do the project again?

What are you going to do with your project?

How long did it take you to finish your project?

Additional Comments?